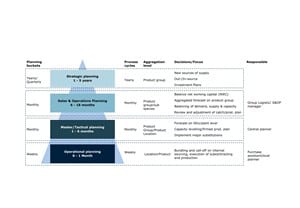

Two large initiatives have been running the last couple of years, namely a Sales and Operation planning(S&OP) implementation, and a Master/Tactical planning implementation.

As illustrated in the figure below, several levels of planning needs to be done in organizations. The S&OP process level is about aggregated volume planning on the long-term horizon, for balancing demand in the market, with the capacity/resources required (whole fish). The Master planning is about planning the more detailed mix (which cuts).

This article will be about the S&OP process implemented, while the article concerning master planning will be covered in the next issue.

Reducing inventories

Since several years, Royal Greenland has been working on optimizing their supply chain planning. Beginning of 2013 this was further professionalized by the introduction of a Sales & Operation Planning process as an enabler for obtaining transparency and for making timely decision in regards to balancing global demand and supply. In other words, does the global Sales & Operation Planning process enable Royal Greenland to exploit the possibilities present throughout their supply chain. This was initiated as a part of the “breaking the curve” initiatives for improving planning, and to reduce inventory levels across the supply chain.

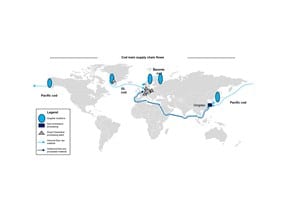

A complex supply chain

Royal Greenland controls an extensive supply chain, from harvesting of raw materials, being fish, to processing and filleting semi-finished goods, to putting it in boxes as finished goods, and further distribution to the retailers and food service. The pushed supply of fish, is a special characteristic of the supply chain context in Royal Greenland. A large proportion of the supply is made up from the fish caught in the waters around Greenland, which is based on the fishing quotas. This makes the supply from Greenland pretty much fixed; however, sourcing of additional fish from other locations around the world is an option, if required. Long lead times, often 6-9 months is an additional factor that increases the complexity and makes it difficult to have a global demand and supply overview, and being able to plan appropriately. To make up for the complexity a high level of expensive inventories are present across the supply chain.

So the fundamental question to be answered for Royal Greenland is: How can we establish a global end-to-end demand and supply plan, for making timely and consensus based decisions in order to reduce inventory levels across the supply chain?

Balancing the aggregated long-term demand and supply

A corner stone of the Sales & Operation Planning process is the aggregated long-term demand and supply balancing. One of the earlier steps in the projects was to establish a long term volume forecast, at an aggregated level, which sales- and category managers are able to give input on. On this level, input regarding market trends, growth initiatives etc. are added to the long term forecast. Structured input meetings with key account managers are scheduled, where input on e.g. contract negotiation/expiration etc. is discussed and incorporated into the forecast as well. This will be the base of an organizational-wide and agreed-upon, consensus forecast.

Implementation of enterprise-wide simulation functionality in SAP, the possibility to break the consensus forecast down into actual raw materials requirements (fish), capacity requirements (machinery, manning etc.) were introduced. This functionality enables three important things:

- The ability to see how much fish, and what type of fish required to produce the demand in the market. As mentioned before the push flow from Greenland determines how much fish is available, and is thus more or less a given. Having transparency of the requirements, enables the possibility to balance this supply of fish, and make timely decisions. Decisions like, do we need to source additional fish from external markets, or do we need to sell off fish, before processing them into finished goods, is an example hereof, which before the S&OP implementation was impossible.

- Secondly, the ability to make timely decisions on adjusting the capacity requirements like the number of production lines, manning, etc. is much easier, when we now to a higher degree, know what the market demands actually will be.

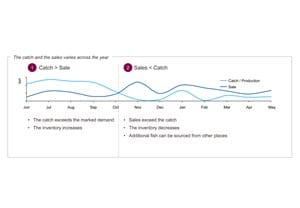

- Thirdly, this enables us to plan the inventories in an appropriate manor. The fishing season is very seasonal, while the demand is pretty stable across year. This means that stock build is a necessity, By adding catch plans (fishing seasons) in the system as well, the ability to match the receipt of fish, with the capacity utilization, enables capacity smoothing across periods

With this data as input, a monthly review- and decision meeting, with organization wide participation, was established. At these meetings representatives from sales and supply meet for the purpose balancing the calculated demand requirements, with the capacity and the constraints that might be, and decide the necessary actions that needs to be done. To support the decisions, an extensive list of KPIs was created, to see catch plans, capacity plans, demand plans, inventory developments, forecast accuracies etc.

Impacts derived from the S&OP Implementation on cod

The impacts from the S&OP process on cod have been substantial. By achieving more transparency on the long term, and by having the ability to more accurately balancing the demand and supply, Royal Greenland has been able to reduce the overall inventory with approximately 10% on average this year, compared to last year, see graph below. It is expected that the reduction will continue, and that 2015 will show a further improvement.

According to Mette Fabricius, S&OP Manager, there are several important decisions that have been taken due to the S&OP process:

“A good example of a decision caused by the S&OP implementation, was to reduce the capacity on our sub-contractor – this had definitely not been done without the S&OP process in place. Another example of a decision derived from a higher level of transparency towards the demand/supply balancing, was that it became clear throughout our organization, that additional sales efforts for increasing demand for cod, was required. This was initiated, and has had a direct effect on our inventory reduction”.

Perspektivering: Reduktion af lagre med mange bindinger

Royal Greenland er en case, hvor Sales and Operations Planning (S&OP) skal optimeres med store sæsonudsving

Før beslutningen om at indføre S&OP havde Royal Greenland gennemført et projekt kaldet ”Breaking the Curve”. Formålet med projektet var at finde initiativer, som kunne reducere lagerniveauerne og derved kapitalbindingen i virksomhedens supply chain. Af det samlede idékatalog blev S&OP vurderet som havende stor effekt på dette.

Hvorfor blev netop S&OP vurderet til at have stor effekt?

S&OP handler om langsigtet balancering af demand og supply, og er dermed et rigtig godt ledelsesredskab til at skabe gennemsigtighed i supply chainen. Der er sæson for fiskeri omkring Grønland i sommerhalvåret, og det betyder at Royal Greenland skal have kendskab til kundernes behov, så de kan hive eksempelvis tilstrækkeligt mange torsk ind til at dække den del af året, hvor man ikke kan fiske omkring Grønland. Hiver man for mange fisk op, får man stor kapitalbinding på lagrene, og hiver man for få op, køber kunderne konkurrenternes fisk. I dette komplekse ledelses dilemma kommer S&OP til sin ret, fordi virksomheden kan planlægge i aggregerede voluminer, som gør at man har overblikket over, hvor mange kilo fisk der skal flyttes gennem deres supply chain.

Hvad er årsagen til at Royal Greenland ikke bare fisker andre steder end i havene omkring Grønland?

Hvis man gjorde det vil en del af bekymringerne om sæsonerne forsvinde. Men Royal Greenland har altid haft stærke bånd til – og rødder i – den grønlandske befolkning, og de har et tæt samarbejde med de grønlandske fiskere. Derfor er den primære forretning fokuseret på fiskeri omkring Grønland og lokale fiskeres mulighed for afsætning af egne fangede fisk. Først herefter supplerer man med fisk fra andre steder i verden for at kunne efterleve forbrugernes efterspørgsel.

Hvad er de overordnede resultater, som forventes efter indførelse af den forbedrede planlægning?

Virksomheden forventer en bedre kapitaludnyttelse i omegnen af 10% year-on-year på en 3 års horisont. De forventer mindre spild som følge af, at man eksempelvis ikke overproducerer eller har for mange ressourcer til det, der skal produceres. Ligeledes reducerer man mængden af stock-outs, hasteordrer og overarbejde. Men det måske vigtigste er, at man får flyttet fokus fra sub-optimeringer i de enkelte funktionsområder, over til et tværorganisatorisk beslutningsforum, hvor beslutningerne træffes.

Seks gode råd i forbindelse med beslutningen om at indføre S&OP:

Få inspiration fra personer og virksomheder som har implementeret S&OP, før du designer dit projekt.

Sæt ambitiøse forretningsmål som S&OP skal opnå.

Involvér alle interessenter som indgår i supply chain processerne, og som skal sikre forankringen af S&OP i dagligdagen.

Design supply chain processerne så de understøtter S&OP principperne.

Sørg for at S&OP i drift er systemunderstøttet, eksempelvis ved implementering af SAP APO.

Vær bevidst om at S&OP er bygget op omkring data, og at dette bliver en ressourcekrævende del af dit projekt.